CAN I REPAIR MY SIDEWALK DURING THE WINTER IN KANSAS CITY METRO & MID-MISSOURI? EXPERTS’ INSIGHTS

Many property owners across Kansas City Metro and Mid-Missouri assume that concrete repairs must wait until warmer weather. But with snow falling and temperatures dropping, you might ask, “Can I repair my sidewalk during the winter?”

In most cases, you can make repairs as long as the temperatures are favorable to the repair materials. It is challenging to work with materials in the cold, but ignoring those leaks can lead to even bigger problems down the road.

That’s where expert guidance comes in! With the right knowledge and tools discussed in this guide, you can tackle those winter repairs effectively and prevent further damage.

CAN I REPAIR MY SIDEWALK DURING THE WINTER?

Yes, absolutely! Just like in other seasons, you can easily make repairs for any kind of damage to your sidewalk. But as the lower temperature in winter is not favorable to most repair materials, you need to go through with special consideration.

Other than that, repairing at the right time is an effective approach to protect your surface from getting bigger issues. Cracking, chipping, flaking, and uneven surfaces in your concrete sidewalk are very common in cold regions, with most caused by the freezing-thawing cycles.

Cold weather can be tough on concrete, and that can lead to more severe issues. So instead you waiting until it is getting worse, repairing early is worth it. But the best is there the complete repair process is done by an expert.

MAJOR THINGS TO CONSIDER FOR SIDEWALK REPAIR DURING WINTER

Though it is possible to start the concrete repair project in winter, it is challenging enough to continue due to constant temperature fluctuation. However, by following some effective tips, you can get it done effectively. Check it out from below:

1. TEMPERATURE LIMITATIONS

Typically the ideal temperature for concrete repairing projects is above 50 degrees Fahrenheit. If it is too cold, it might not harden properly. Also, you have to struggle with the proper alignment of the concrete on the surface.

2. MATERIAL SELECTION

Cold temperature significantly impacts the repairing material. In colder weather, there is a higher chance of the material’s surface layer drying out before fully setting and cracking as a result.

Most of the materials like concrete, mortars, coatings, and sealants are hard to work with when the temperature is below 5°C. For instance, you should check the material-specific data sheet to ensure you’re using them at the right temperature.

3. PROPER CURING

When it’s cold outside, new concrete can freeze and you can’t set it right. To prevent this, it is best to cover the concrete surface using heating blankets. It helps warm up cold concrete surfaces and removes snow faster. You will get the area cleaned and prepare it for repairs.

4. ADD ANTIFREEZE

When it’s winter, the constant reducing temperature can cause the water in concrete to freeze. To deal with this, our experts at PolyMagic use antifreeze properties in the concrete mixture. Antifreeze is a special liquid that slows down the freezing process of concrete water and prevents potential cracks or damage.

5. CONSIDER TEMPORARY FIXES

If you find it hard to cope with the repair material, a temporary fix is like a quick solution to keep the concrete from getting worse. You can wait for warmer weather to do the full repair. It lessens the chance of making the damage bigger.

BENEFITS OF REPAIRING YOUR CONCRETE SIDEWALK IN WINTER?

Repairing your sidewalk even offers far more benefits. Colder winter can make your damaged path get worse, so it is the right time to start repairing and stop more damage. Have a look at why repair in winter is worth considering.

1. FASTER PROJECT SCHEDULING

As winter comes, fewer people head to fix sidewalks or do big outdoor projects. That means the construction companies aren’t as busy, and you can make your schedule sooner. You won’t have to wait as long as you would in the busy summer.

2. SAME EFFICIENT TURNAROUND TIME

Even though it is cold outside, the repair project will still be done with quality. Professionals use special tools like heating blankets to ensure your sidewalk repair is done as fast as it would be in warmer weather.

3. GUARD AGAINST COLD AND THAW

With the dropping temperature in winter, freezing and thawing are common issues in concrete. Even small cracks in concrete can get bigger due to this factor and start to break apart or crumble at the worst parts.

So by fixing your concrete before winter, you reduce the chances of damage from these cycles. A smooth surface lowers the chances of falling or slipping. This adds an extra safety layer for your friends and family.

4. LONGER-LASTING REPAIRS

For any type of repair, whether it is a concrete project or other material, moisture control is the key. Excessive moisture can prevent the needed bonding of the repair materials. That’s where you can get benefits in winter. If the repair materials are poured under the right temperature, you ensure long-lasting solutions.

MAJOR SIGNS THAT YOUR SIDEWALKS NEED TO BE REPAIRED

It’s important to pay attention to the appearing damage on your sidewalk on time. For instance, you can look for the major signs listed below.

- Appearance of Cracks: When the temperature drops, the soil underneath your concrete sidewalk starts to expand and contract due to cold and thaw cycles. This puts pressure on the concrete and forms cracks.

- Potholes: Potholes are another concrete issue that is commonly found in high-traffic areas. They often start with small cracks and then expand to up to a meter wide and 10.

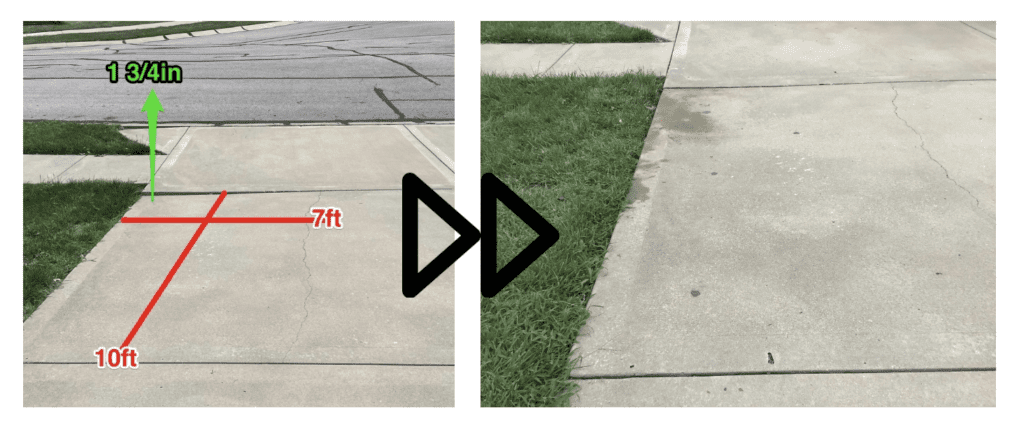

- An Uneven Appearance: If you notice your sidewalk appears uneven, it is a sign that you need repair work. If unnoticed, it may lead to bigger issues like crumbling and breaking.

- Discoloration: Discoloration is one of the major signs that your sidewalk needs resurfacing. It not only affects the appearance of the concrete but also causes many more issues. That includes mold growth, excess moisture, and damage to the slab.

- Flaking: When you find peels or chips away at the top of your concrete layer, it’s best to head over to an expert concrete manufacturer company in Kansas City. Some areas in the city get as many as 99 freeze-thaw cycles in one winter, which can lead to bigger issues.

EXPERT TIPS TO KEEP YOUR SIDEWALK IN TOP SHAPE IN WINTER

If you want to prevent all the unexpected damage to the concrete’s surface and integrity due to temperature fluctuations in winter, our expert suggestions can guide you here:

- For colder temperatures, you can consider laying your sidewalks with a de-icing agent like calcium chloride. Calcium chloride lowers the freezing point in the ice and prevents it from freezing.

- Also, you can seal your concrete with a high-quality sealer. It creates a hydrophobic water barrier on the surface and allows the water on the surface to turn into droplets instead of soaking in.

- If you’re noticing some micro-cracks, don’t use gel injections. Instead, contact a professional and make arrangements to seal the area properly.

- Make sure to shovel snow regularly, especially after a heavy snowfall. This will prevent ice buildup and potential damage.

- As a pre-treatment measure, you can apply a brine solution to your sidewalk before a snowstorm comes. It prevents ice from bonding to the concrete effectively.

To get more in-depth insight into your sidewalk issue and how to repair the damage, we recommend consulting our specialists at PolyMagic. We have years of experience in this industry, and our team is ready to help you protect your concrete surfaces and ensure they last through winter. Contact us today for a consultation and keep your sidewalks safe and sound!